Description

Water Supply Booster Pump Price and Influencing Factors

A water supply booster pump is one of the widely used devices in industrial sectors and domestic applications. In English, the word "booster" means "enhancer" or "amplifier." This equipment consists of connecting one or more electric pumps in parallel to an intelligent control panel for management. Nowadays, especially due to the expansion of construction and the presence of residential towers with many floors and great height, our need for booster pumps has increased significantly. This is because the height and length of the piping cause water pressure drops, and this equipment enables water to be delivered with a constant and optimal pressure to all points of a residential, industrial, or urban building, ensuring uniform consumption.

There are many factors that affect the price of a booster pump, and we will highlight the most important ones.

- The type, brand of the pumps used, and their manufacturer

- Type of Body Material

- Material of Fittings and Pipes

- Geographical and Environmental Conditions of Booster Installation, such as Humidity and Temperature

- Operating Pressure

- Number of Units, Height, and Number of Floors Covered by the Booster

- Type and Brand of Electrical Components and Control Panel Equipment, such as Cables, Drive (VFD), PLC, and Other Devices

- Type of Usage, such as Potable and Sanitary Water

- Whether the Booster is Fixed Speed or Variable Speed

- Installation of Jockey Pump and Expansion Tank

Water Supply Booster Pumps

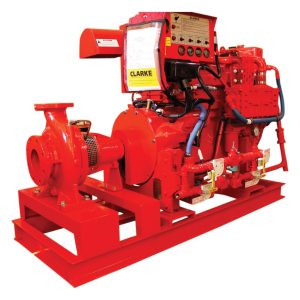

Fixed Speed Water Supply Booster Pump

In general, fixed-speed booster pumps operate using a contactor and direct start method, and instead of a transmitter, a pressure switch is used. Because this type of booster pump does not use a variable frequency drive (VFD) to control motor speed, water pressure fluctuates during motor start and stop, often causing slight water hammer. However, fixed-speed boosters are much more economical compared to variable-speed ones since drives and PLCs are eliminated, reducing the overall cost.

Variable Speed Water Supply Booster Pump

Pump startup is performed smoothly thanks to the use of a variable frequency drive (VFD). This ensures water is delivered at a constant and optimal pressure throughout the system. No floor experiences fluctuations in water pressure, and water is distributed evenly to all points. Additionally, the lifespan of pumps, mechanical components, and electrical equipment reaches its maximum in this type of booster pump.

The operation of this type of booster pump is highly precise, providing excellent safety and protection. As a result, it offers very low power consumption and high efficiency, which are among its most significant advantages.

How Variable Speed Water Supply Booster Pumps Work

The control system of the water supply booster pump is equipped with a pressure transmitter sensor that receives the pressure signal from the pump discharge section and sends it to the Programmable Logic Controller (PLC). Based on the setpoint, the PLC adjusts the motor speed using an inverter (variable frequency drive). A PI controller is used to prevent motor speed fluctuations caused by pressure gradients. In this method, the pressure must remain constant at all times, with the only variable factor being the pump motor speed. Therefore, even with changes in consumption patterns, the system consistently maintains a stable pressure.

The booster set controller must have a changeover mechanism for the pumps. This mechanism acts as a maintenance system, reducing failures and the need for repairs. The pump switching mechanism is fully automatic and logical, depending on consumption load, pump operating hours, and faults.

The consumption load is distributed among the main pumps, and the system determines which pump should start first in each operational cycle. For example, if the controller detects that pump A started in the previous cycle, it will start pump B first in the next cycle. Additionally, the pump with the highest operating hours is stopped, and the pump with the lowest operating hours replaces it. This setting can also be based on a timer defined by the operator.

This rotation between main and standby pumps prevents failure, wear, tear, and impeller locking. Moreover, the control system is equipped with automatic pump backup, so if a fault or error occurs, the next pump automatically takes over, ensuring uninterrupted system operation.

Why Do We Need a Water Supply Booster Pump?

Building installations generally refer to creating suitable living conditions and are, in fact, a vital and essential part of any building that always receives attention. This aspect of construction is carried out according to careful planning and engineering designs, leading to improved quality of life, optimized energy consumption, and increased building lifespan.

Providing the necessary cooling and heating for buildings, as well as supplying clean drinking water at appropriate pressure, are essential needs today. Addressing potential hazards such as fires and earthquakes, as well as sewage disposal, are among the critical issues that can be managed through the implementation of installations and equipment like booster pumps.

How to Choose a Booster Pump?

- Determining the Required Capacity Based on Daily Consumption

- Considering the Building Height and Length of Piping Route

- Selection Based on Pump Noise and Vibration Levels

- Checking Warranty and After-Sales Service

- Section 3: Price Inquiry and Purchase

- Expert Consultation for Choosing the Best Booster Pump Model

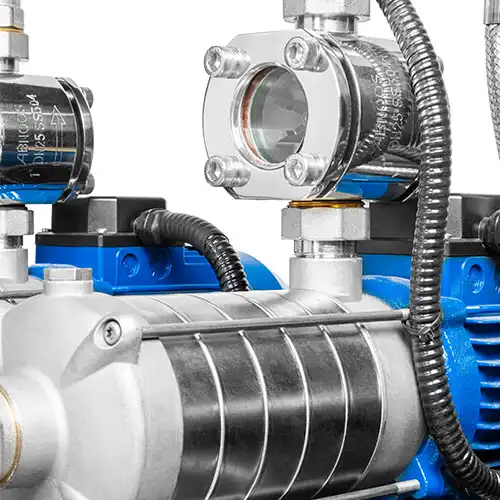

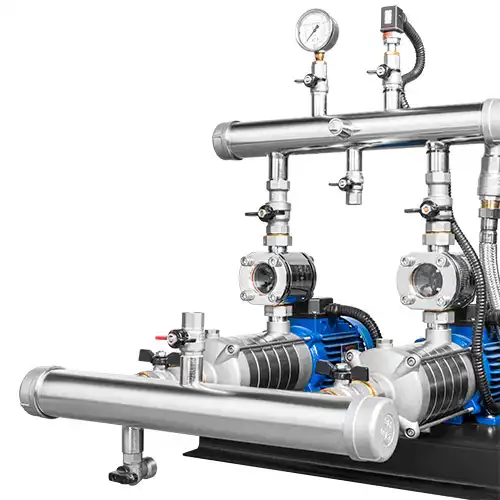

Components of a Water Supply Booster System

A booster pump is composed of various components.

These components include:

- Pump: Acts as the main driving force responsible for pumping and transferring water.

- Control Panel: Responsible for controlling and directing the pumps based on their mode of operation (fixed or variable speed).

- Inlet and Outlet Collectors: Serve as the points for water intake and supply to the pumps, as well as the outlet for delivering water to the consumers.

- Fittings: Such as couplings, nuts, flanges, elbows, etc., used to connect pipes, valves, and other equipment to each other.

- Base Frame: Used to integrate all equipment, pumps, and control panels onto a single structure.

- Diaphragm Tank: Serves as an auxiliary to the main pumps for handling minor and short-term demands, which is very beneficial in extending the lifespan of the pumps.

All-stainless steel booster pumps are made from 304 stainless steel and, due to their high resistance to corrosive materials and fluids, are widely used in various industrial and commercial applications such as food, hygiene, pharmaceutical industries, water pressure boosting, ventilation systems, and irrigation.

Compared to cast iron pumps, these pumps offer higher resistance and efficiency, as well as a lighter weight.

Advantages of Using Booster Pumps

- Our daily activities are entirely dependent on water. From using the washing machine, washing hands and clothes, to taking a shower, a water booster pump can help people by providing the desired water pressure for everyday use. Using a booster pump offers many advantages such as increased water pressure, improved water circulation, extended lifespan of appliances, and more.

- It allows you to use water at a constant and optimal pressure.

- It offers easy installation and transportation.

- It is suitable for various commercial, industrial, and residential applications.

- It requires less maintenance, resulting in a longer lifespan, because it is precisely controlled by a PLC.

- Reduction of noise or sound pollution caused by pump operation.

Maintenance and Care of Water Supply Booster Pumps

- The booster pump and all its components should be regularly checked by the boiler room operator. Additionally, attention to the following points is recommended:

- The operating noise of the booster set should be normal and similar to the startup moment; if any abnormal noise occurs, the cause must be investigated.

- The foundation must be designed so that, over time, the booster frame does not become unlevel or misaligned.

- Check the check valves, shut-off valves, and collectors for proper performance and quality.

- If the water inside the tank is drained and then refilled, the pumps must definitely be vented (air purged).

- The air pressure inside the diaphragm tank should be monitored by the operator, and the integrity of the diaphragm must be ensured.

- Due to mineral deposits inside the water pipes, after some time, the settings on the control panel—especially the desired output pressure—may need to be reviewed and adjusted.

- The filter should be regularly cleaned by the operator.

- The proper functioning of fuses, panel indicators, and switches must be thoroughly checked. Additionally, the electrical wiring connections should be inspected.

- The operator should check the set desired output pressure.

- Abnoos booster pump control panels are equipped with an automatic dry-run protection system. Therefore, if there is insufficient water in the suction collector, the booster pump will not start. If the pump is manually started without adequate water presence, it will be damaged. Hence, it is strongly recommended not to manually start the booster pump without first ensuring sufficient water in the suction collector.

- The booster pump should be installed in a clean, dust-free environment to prevent any corrosion and rust.

مهدی یعقوبی –

قیمت لطفا

hossein taalifard –

سلام، لطفا با شماره ۰۲۱۹۱۰۰۷۹۷۲ تماس بگیرید.