| TYPE | NOMINAL POWER | INPUT POWER | AMPERE | Q =CAPACITY | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single-phase | Three-phase | P2 | P1 | Single-phase | Three-phase | m3/h | 0 | 1.8 | 3.6 | 5.4 | 7.2 | 10.8 | 13.2 | 15.6 | 16.8 | 18 | |

| lt/1’ | 0 | 30 | 60 | 90 | 120 | 180 | 220 | 260 | 280 | 300 | |||||||

| 230V-50Hz | 230/400V-50Hz | HP | kW | kW | 1 x 230V | 3 x 400V | Total head in meters w.c. | ||||||||||

| MULTI-X 10-4 | MULTI-XT 10-4 | 2 | 1.5 | 2 | 9 | 3.9 | H(m) | 44 | 42 | 40.5 | 39 | 37 | 30 | 25 | 19 | 15.5 | 12 |

| MULTI-X 10-5 | MULTI-XT 10-5 | 3 | 2.2 | 2.5 | 12 | 4.5 | 54.5 | 51.5 | 50 | 48 | 45 | 36.5 | 29.5 | 21.5 | 17.5 | 13 | |

| MULTI-XT 10-6 | 4 | 3 | 3.2 | 7 | 66 | 63 | 60.5 | 59 | 56 | 45.5 | 36.5 | 26.5 | 21 | 15.5 | |||

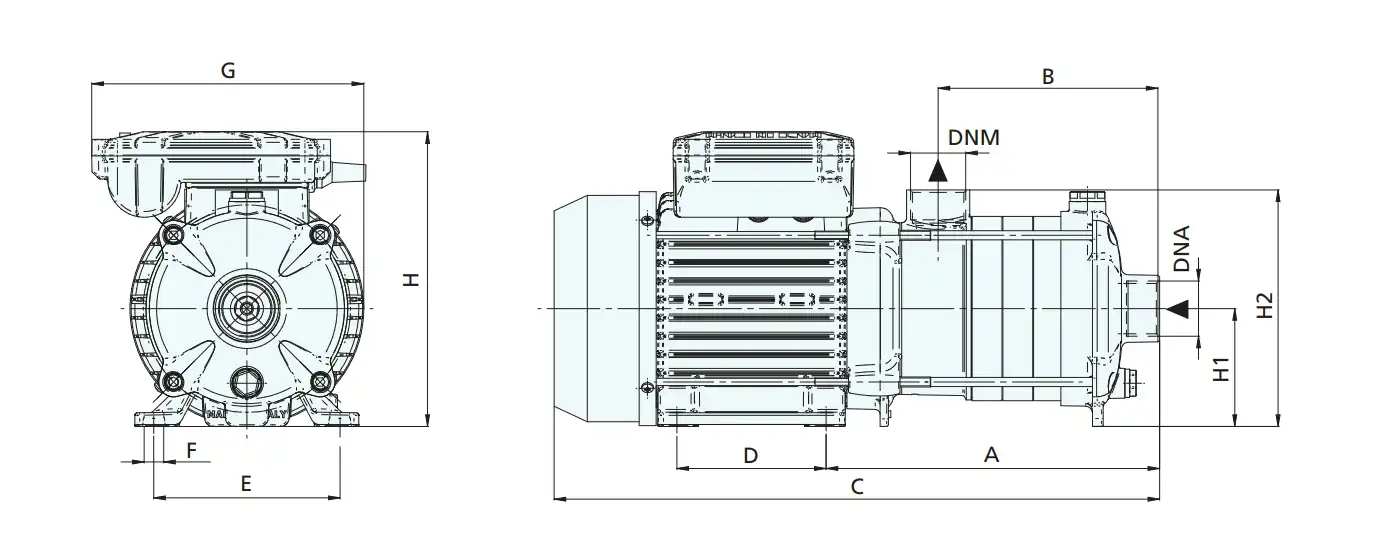

| TYPE | DIMENSIONS mm | DIMENSIONS mm | WEIGHT | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Single-phase | Three-phase | A | B | C | D | E | F | G | H | H1 | H2 | Impellers Giranti | DNA | DNM | P | L | H | Kg |

| MULTI-X 10-4 | MULTI-XT 10-4 | 263 | 169 | 483 | 125 | 140 | 10 | 200 | 230 | 90 | 200 | 4 | 1” | 1” | 212 | 554 | 245 | 21.2 |

| MULTI-X 10-5 | MULTI-XT 10-5 | 293 | 200 | 513 | 125 | 140 | 10 | 200 | 230 | 90 | 200 | 5 | 1” | 1” | 212 | 554 | 245 | 22.5 |

| MULTI-XT 10-6 | 324 | 230 | 543 | 125 | 140 | 10 | 200 | 230 | 90 | 200 | 6 | 1” | 1” | 226 | 530 | 278 | 26.7 | |

| Stainless Steel Horizontal Multistage Pump MULTI X | |

|---|---|

| Application | - Domestic applications – Water distribution systems – Various types of booster pumps – Firefighting equipment – For pressure boosting |

| Features | – Pressure supply capability – Minimum energy consumption – High reliability and efficiency – Low noise – Low wear and tear |

| Operating Condition | – Flow rate: Maximum 18 cubic meters – Head: Maximum 66 meters – Allowed fluid temperature: up to 90 degrees Celsius – Ambient temperature: up to 40 degrees Celsius – Maximum suction depth: 7 meters |

| Motor | – Voltage: 230/400 volts (single-phase / three-phase) – Frequency: 50 Hz – Protection rating: IP55 |

| Material | – Pump body: Stainless steel – Impeller: Stainless steel 304 – Shaft: Stainless steel 304 – Seal: Ceramic/Graphite/VITON |

Abnoos Company began its operations in 2012 with the aim of localizing the production of industrial valves and water supply and firefighting booster pumps, on a land area of 10,000 square meters.

Abnoos distinguishes itself as a trendsetting manufacturer through its in-house Research and Development unit. By adhering to the principles of responsibility, quality, and innovation as our core policy, we strive to achieve our goal of developing knowledge and products that meet the highest standards. At Abnoos, precise design and strict quality control in product manufacturing are integral to our work approach, ensuring the reliable performance of our products in delivering high-quality water and fluid flow in water supply systems and industries that utilize them.