Description

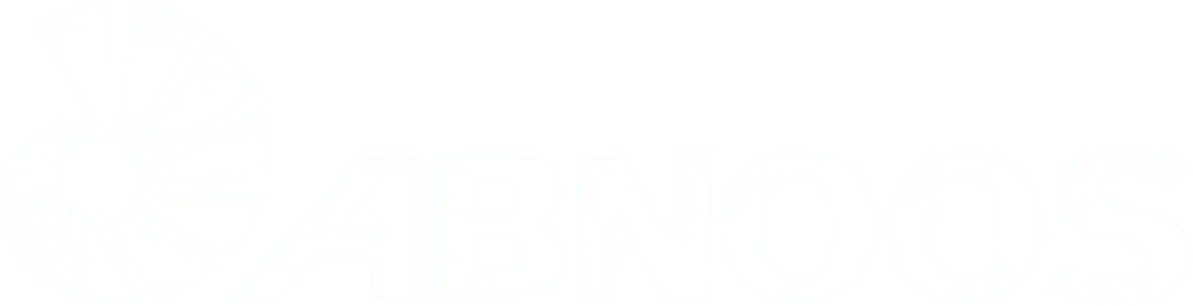

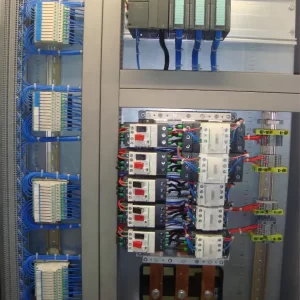

Main components of the control panel, such as Contactor، Bimetallic relay، Thermal switch، Miniature circuit breaker،Automatic main switch With brand SchneiderFan: bearing typeTerminal and rail ها Raad And the enclosure has an IP54 protection rating, made of 1.5mm thick sheet metal with electrostatic paint, and includes:

- Intelligent control system

- Main rotary switch beside the panel, Schneider brand / Tavan Rah Sanat

- Key switch / vertical, MITO brand; phase control, Borna / Shiva brand; fan vent, MITO / OSKAR brand.

- Cable brands: Zarsim / Khorasan / Hamedan / Ri Afshan.

- Speed control using Danfoss inverter (in variable-speed models)

- The panel is equipped with a Delta PLC with analog inputs and outputs in the variable-speed models, along with a 7-inch Delta HMI monitoring system. (Includes a 5-year warranty)

- Gradual increase and decrease of each pump's speed according to consumption, resulting in the elimination of water hammer and extended lifespan of the pump’s moving parts (in variable-speed models). Also features PID control and a unique program from Grundfos (Hydro MPCF).

- Automatic and manual selection system for testing or removing any pump from the circuit in case of a technical fault.

- Pump start slip and frequency control system to prevent pressure fluctuations.

- Self-service system in fire-fighting booster pumps.

- Auto Change Over (ACO) systems (ensuring each pump operates equally) in ON/OFF mode.

- Time Changing

- Signals the system and shuts it down when there is a water shortage in the circuit, and automatically restarts once the water shortage is resolved.

- Protection of the electric pumps against overload by connecting the motor PTC to the PLC, with each alarm having a separate command.

- Protection of the electric pumps for phase sequence and phase number.

- Use of a contactor and main switch rated 40% higher than the current drawn by the electric motor during direct-on-line startup.

- Control to prevent the electric pumps from turning on or off due to pressure fluctuations and to avoid simultaneous operation.

- Equal distribution of operation among all main electric pumps, so that the running time is shared evenly across all pumps.

Safety and protection systems

- Water shortage safety system in the tank, indicated via an alert on the HMI screen.

- Safety system for detecting and preventing operation of the pump without water.

- Phase control safety system to prevent phase loss and fluctuations in voltage and current.

- Ground (earthing) safety system for protection in case of phase-to-ground faults.

Reviews

There are no reviews yet.