Description

Lighting Distribution Panel (LDP)

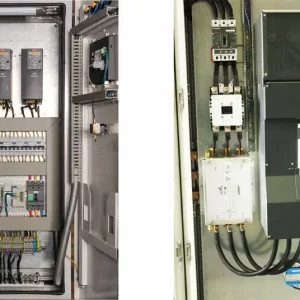

An electrical distribution panel is one of the main components in a power supply system, used to organize electrical branches and circuits. It is responsible for controlling and managing the distribution of electricity in a building or industrial facility. One of the most commonly used types of panels is the lighting distribution panel, which is typically made in either metal or non-metal materials, affecting the overall cost of the panel.

A key advantage of lighting distribution panels is that they are easy to maintain and repair. Additionally, these panels play a crucial role in protecting human life against electric shock.

For supplying electricity to residential, industrial, and commercial units, the use of electrical panels is necessary. These devices organize the distribution of electricity in a completely orderly manner.

In general, we should understand that electrical energy enters the main distribution panel from the meter. This panel contains automatic switches to distribute electricity to various sections, one of which is the lighting section, which then feeds into the lighting distribution panel (LDP).

Components of a lighting distribution panel:

• Contactors and relays: Used to control and regulate the electrical current and to switch various devices, such as pumps, on and off.

• Electrical panel communication components: including cables, wires, and busbars, which establish connections between power and control devices.

• Switches and circuit breakers, including fuses, to protect equipment and devices against overcurrent.

• Terminals: For connecting and managing wires and cables, as well as providing safety and preventing unauthorized access inside the panel.

• Signals and Push Buttons: Used to display the status and operation of various components of the distribution panel and to control start and stop commands.

• Ammeter, Voltmeter, Timer, and Other Measuring Instruments: Used to detect and measure parameters such as voltage, current, and time.

Price of Lighting Distribution Panels and Factors Affecting It

1- Panel frame dimensions and size (larger panels increase the price)

2- Type and model of the frame: wall-mounted, surface-mounted, recessed, freestanding, or modular, with or without a cover.

3- Material used: plastic, galvanized iron, painted steel, or stainless steel. This is one of the most important factors in determining the price of the panels.

4- Thickness of the panel body and tray sheet.

5- The material, quality, and brand of the internal components of the panel (using high-quality and reputable brand components can increase the price).

6- The complexity of the panel design and control scenario (more intricate designs and control scenarios for companies result in higher costs).

7- Technology and smart features of the panel: Panels equipped with special functionalities such as remote control, BMS integration, or smart lighting settings have higher prices.

8- Manufacturer brand: Panels produced by well-known and reputable brands, offering long-term warranties and guarantees, are priced higher.

9- All Abnoos electrical panels, including lighting panels, are equipped with an internal light that enhances the panel’s aesthetics and provides the necessary illumination for operators to see clearly at night.

In general, low-voltage panels are manufactured in various types, including motor control panels, main distribution panels, capacitor banks, and industrial or smart control panels. Since each of these panels serves different applications, their prices vary accordingly.

Reviews

There are no reviews yet.