Description

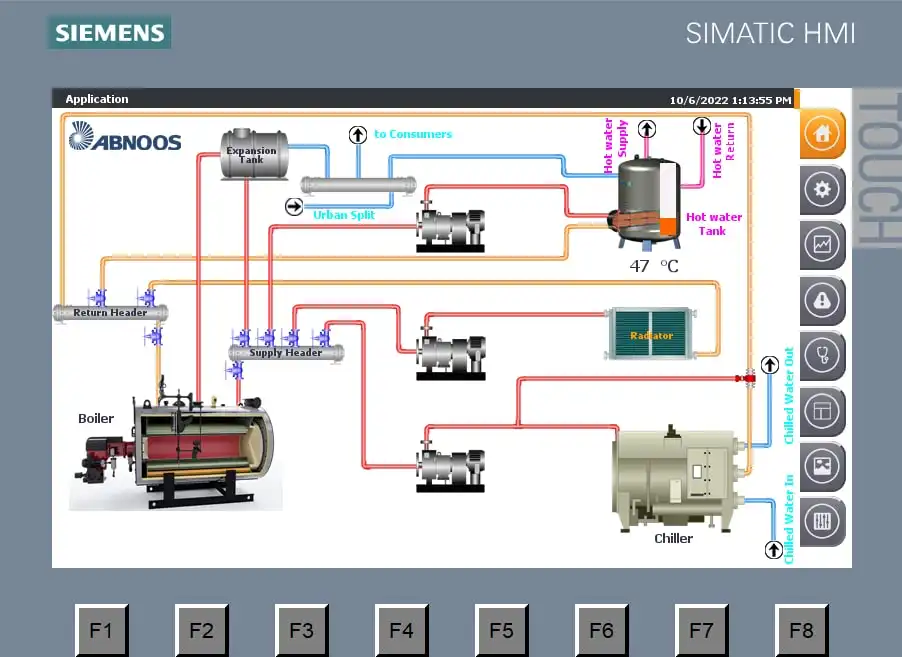

Smart Boiler Room Control PanelIt is a system through which boiler room equipment (water supply, air ventilation, cooling, and heating systems) is controlled and programmed according to the building’s needs, ensuring optimal performance of these systems. The system detects requirements using sensors inside and outside the building, taking environmental conditions into account. This not only reduces fuel consumption in the boiler room but also decreases equipment wear and tear, thereby ensuring residents’ comfort at standard levels.

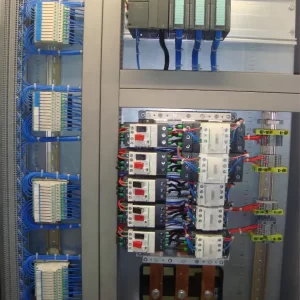

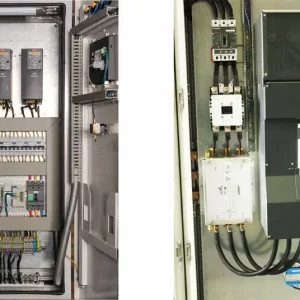

Industrial control panels, which are a subset of Industrial Control Panel They are used for controlling and monitoring equipment and processes. Components of these panels include contactors, timers, PLCs, and HMIs. The automation technology in these panels enhances process efficiency and accuracy. Control panels are made of various devices that can monitor system status in different conditions, apply settings to the system, display information, and, if needed, allow operators to make adjustments to meet the electrical network’s requirements.

Machine and production line control systems use PLCs and HMIs for process control, parameter adjustment, and monitoring. Today, PLC-based control panels are used to significantly reduce wiring complexity and panel size, making troubleshooting easier. Process control panels are employed to manage and monitor industrial and manufacturing processes. These panels rely on PLC and HMI systems to perform their functions and are widely used in petrochemical, water and wastewater, and chemical production industries.

The intelligent control system is used in modern boiler rooms and, while optional, is highly practical. In this setup, the boiler system is no longer operated manually by a user for turning on, off, or adjusting settings. Instead, numerous sensors and actuators are connected to a central processing system, which operates based on data received from the sensors and the programmed instructions provided to the central system.

A decision regarding the adjustment of the boiler room is made and applied to the system via actuators. For example, a boiler can act as an actuator, where its burner is turned on or off based on commands from the central processing system.

Reviews

There are no reviews yet.