Description

A wafer-type disc check valve (wafer check valve) is a protective device used in piping systems such as residential plumbing, boiler rooms, sewage, power plants, agriculture, water treatment plants, chemical industries, and others. Its function is to block any reverse flow in the system.

Check valves come in various types. The wafer-type flanged lift check valve is one such type, designed for flanged connections. Due to its compact size and light weight, it is especially useful in tight or confined spaces. This valve operates automatically without the need for an operator, so it can be classified as an automatic or self-acting valve. Its design features a disc that moves back and forth to open or close the fluid flow.

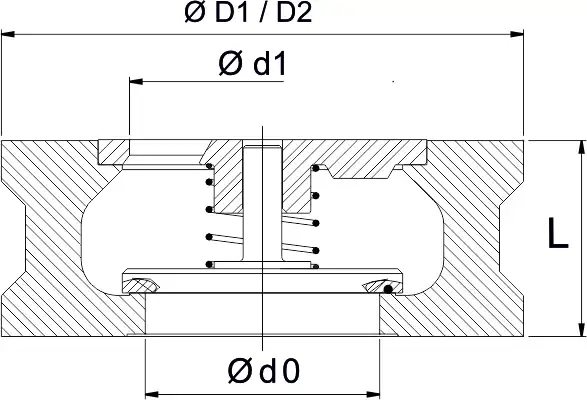

Wafer Type Flanged Check Valve The wafer-type valve is composed of four main parts:

- Body

- Disk

- Spring

- Spring retainer

In this type of Wafer Type Flanged Check ValveIn this type, the disc rotates 90 degrees in the direction of the fluid flow, and its movement is controlled by a spring positioned behind the disc. The main body is designed to surround the disc completely. When the force exerted on the disc by the pressure of the flowing fluid exceeds the resistance force of the spring, the disc lifts from its seat, allowing the fluid to pass through.

When the pressure difference inside the valve decreases, the spring exerts force on the disc, causing it to return to its seat and close the flow path before any reverse flow can occur.

When the pressure difference inside the valve decreases, the spring applies force to the disc, causing it to return to its seat and close the flow path, preventing reverse flow. The wafer check valve can be installed vertically, horizontally, or at an angle. Due to its wide range of applications—including hot liquids, steam, gas, condensate systems, and more—it has become a highly versatile and widely used valve in the heat exchanger industry.

Reviews

There are no reviews yet.